OVERVIEW

The ONV-IoT9000-CK-SI intelligent power box is an intelligent power control system with high integration, strong functionality, and simple installation. It adopts a modular structure, 1 main control unit, multiple groups of voltage detection, and back-end platform remote control output. The device supports 5*card modules, and each card module supports 4*separate power output and can be expanded to 20*output monitoring and control. The output power can be customized according to the project, and AC220V, AC24V, and DC12V are available to meet the needs of various application scenarios. It can be flexibly configured according to the project situation.

The ONV-IoT9000-CK-SI has a built-in core control unit with stable performance, which can realize the city power monitoring detection of front-end equipment and the monitoring and control of power-consuming equipment, including fan temperature control, remote control of output power, network transmission monitoring and signal transmission, front-end box working environment temperature monitoring, box anti-theft and other functions. It is uploaded to the monitoring center's operation and maintenance platform in real time through the network. When there is a network interruption, equipment damage, city power outage, equipment power consumption status change, box temperature is too high, and the box door is forced to open, the back-end management platform will be notified in real-time. It is widely used in the construction of smart security IoT projects including safe cities, smart transportation, smart cities, municipal facilities and environmental management, natural disaster monitoring, water conservancy facilities monitoring, and communication base station monitoring.

FEATURE

Security

◇ 1*Box door status detection alarm switch, the back-end management platform can monitor the box door status in real-time, and can set the arming and disarming modes.

◇ The built-in 40KA power supply anti-surge and lightning protection module can effectively reduce the damage to the internal equipment caused by the surge current and ensure the stable operation of the equipment.

◇ When power failures such as leakage, overvoltage, Undervoltage, overcurrent, short circuit, etc. occur, the reclosing switch can automatically disconnect, automatically detect whether the fault has been eliminated at intervals, and automatically close the switch when the fault is detected to be eliminated, and restore normal working state. At the same time, the corresponding power (voltage/current/power) data and the number of lightning strikes are transmitted to the back-end operation and maintenance management platform in real-time.

Online monitoring

◇ Support real-time monitoring of the box environment and real-time linkage with the operation and maintenance management platform, including unpacking alarm, power failure alarm, network disconnection alarm, water leakage alarm, temperature and humidity alarm, unpacking lighting, etc.

Power monitoring and control

◇ Support 5*card module combination, each module supports 4*power output, provides AC220V, AC24V, and DC12V optional, the output power can be flexibly configured according to the project situation and can be expanded to 20 power outputs at most. The system can monitor the output voltage and current in real-time, and upload the power status and fault information to the back-end management platform in real-time.

Network communication monitoring

◇ Provides 1*10/100M RJ45 port connected to the switch or other network devices, which can realize network status monitoring and remote restart of network devices, and upload network status and fault information to the management platform in real-time. Support network watchdog function, and can automatically analyze and judge the network status, when the network port communication is abnormal, it will automatically restart the switch power supply to restore normal network communication.

Remote control

◇ Support remote restart of cameras, switches, and PON equipment power supply to achieve remote fault repair.

Fan control

◇ The temperature linkage value inside the box can be set remotely. When the temperature reaches the set value, the fan will automatically start working and monitor the temperature inside the box in real-time. When the fan works abnormally, a high-temperature warning will be issued. The backend operation and maintenance management platform can also control the fan on/off.

Lighting control

◇ The operation and maintenance controller has a built-in light sensing control circuit and provides 1*DC12V LED light connection interface, which can be connected to the LED light in the box. When the box door is opened or the ambient light is low, the LED light in the box automatically turns on, which is convenient for the inspection and maintenance of the equipment; at the same time, it can monitor the working status of the light in real-time, and the on/off status of the light is synchronously displayed on the platform, and the on/off of the light can also be controlled.

Box door anti-tampering detection

◇ The operation and maintenance module provides a 1*access control detection interface, which can be connected to the box door detection switch to detect the box door status and prevent the power box from being abnormally pried open and the equipment from being stolen. Supports multiple mode settings such as arming, disarming, and automatic disarming.

Real-time status query

◇ The main control unit is equipped with a high-definition OLED display, which can directly query the status of the box environment variables (switch, fan, temperature/humidity), power supply working status, network communication status, and other information so that the maintainer can quickly detect the working status of the box.

Efficient operation and maintenance (O&M)

◇ Use the O&M App mobile phone to scan the code to quickly and automatically enter the management platform system. No configuration, simple and convenient.

◇ After connecting to the Internet, it can be linked with the platform in real time, remotely manage and view the operation of the front-end equipment, monitor the power supply status of the equipment, locate the installation location, realize fault alarm, fault location, remote control, automatic dispatch, etc., monitor the operation status of the power box in real time, and realize the intelligence and automation of the system.

◇ When the front-end equipment is abnormal, the alarm information will be reported to the platform or the management personnel will be notified. The platform will intelligently classify whether to generate a maintenance work order and form a QR code dispatch work order. The maintenance personnel can view the dispatched work order on the mobile APP and troubleshoot the problem in time. The centralized management cloud platform has alarm records, historical operation records, fault statistical analysis reports, and operation log records. All report records can be exported to provide data support for the improvement and optimization of the comprehensive operation and maintenance system.

◇ The mobile APP O&M terminal support real-time reception of work order alarm information. The front-end equipment fault alarm information is reported to the platform in real-time or notified to the management personnel through information. The platform intelligently classifies whether a maintenance work order is generated and forms a QR code work order. The maintenance personnel can view the dispatched work order through the APP and troubleshoot the fault in time. Supports real-time positioning of the movement trajectory of maintenance personnel, supports convenient maintenance operations such as uploading of on-site fault pictures and online material claiming.

Centralized and efficient O&M of the back-end management platform

◇ Support custom fault alarm type and fault alarm priority setting.

◇ Real-time viewing of front-end equipment, unified deployment, unified management, and remote control.

◇ Support custom editing of network topology, and visualization of on-site physical connection platform, making operation and maintenance more intuitive and more accurate.

◇ Support fault alarm records, historical operation records, fault statistical analysis reports, operation log records, work order dispatch records, work order processing execution record reports, and summary analysis and report export functions.

PRODUCT INNOVATION

◇ Data collection: Real-time display of voltage, current, network, temperature, and other data of remote monitoring equipment.

◇ Fault location: It can locate the causes of circuit faults, network faults, heat dissipation faults, equipment faults, etc., and provide decision support for managers.

◇ Permission management: Set the operating permissions of supervisors, divide the business work content, and all operations have detailed log records for backup.

◇ Remote control: For common minor faults such as equipment freezes, the equipment can be remotely controlled to restart, greatly reducing the workload of fieldwork.

◇ Data mining and analysis: The system can archive and store multi-dimensional regulatory data. After data mining and sorting, it can realize applications such as fault classification statistics and trend analysis.

◇ Asset management: Inventory key equipment asset ledgers, classify and screen asset attributes and operating status, classify and count asset availability indicators, and display them intuitively with visual charts.

◇ Stable and flexible: The platform software runs on the Linux operating system, which is reliable, stable, and flexible to deploy. It has a communication interface that can be smoothly connected with third-party software systems.

◇ Ubiquitous connection: It can connect to various scene perception systems, and the corresponding system data and dashboards can be directly called on the management platform to simplify multi-system access and compatibility issues.

◇ Log audit: The platform automatically records logs from sources such as management operations, operation and maintenance operations, work order flow, network security, inbound and outbound traffic, etc., and can generate risk warnings after auditing important logs.

◇ Work dispatch management: One-click dispatch can be performed for reported faults, and work orders are generated and pushed to field O&M personnel on the APP, the entire process of work order flow is tracked and work order KPI assessment reports are generated.

◇ Intelligent alarm: When abnormal conditions occur in the front-end network, power supply, and working environment, the system intelligently triggers early warning or alarm actions through data analysis, pushes the cause of the fault and specific data to the large screen, and accurately locates the alarm location on the GIS map.

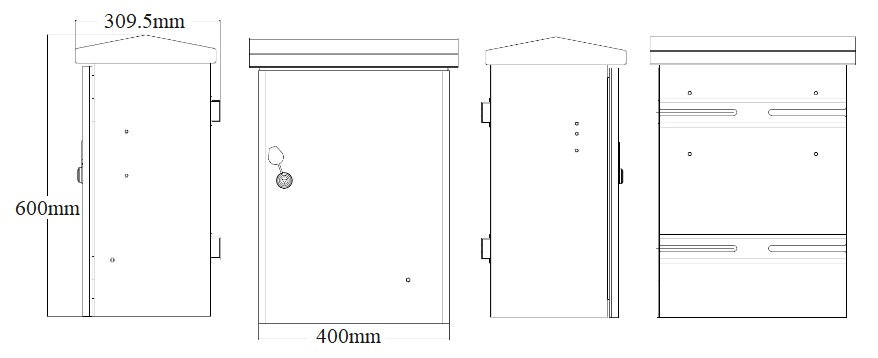

DIMENSION

DEFAULT CONFIGURATION

|

ONV-IoT9000-CK-SI |

|||

|

No. |

Model |

Product Name |

Description |

|

1 |

IoT9000-DG-CK |

Galvanized steel box |

1.2mm thick galvanized steel sheet. 600*400*309.5mm(L*W*H) |

|

2 |

IoT90-CZ250-10A |

3-hole socket |

3-hole socket 10A/250V |

|

3 |

IoT90-KK2P250-16A |

2P Air circuit breaker |

2P bipolar Air circuit breaker 16A/400V, rated short circuit: 6KA |

|

4 |

IoT90-CH175275-16A |

Auto-reclosing |

Working voltage: 175-275VAC 50-60Hz, Rated power: 16A |

|

5 |

IoT90-SPD-220AC |

AC power SPD |

2P power SPD, rated voltage Un: 220V, Max current capacity: 40KA |

|

6 |

IoT7000-G2000-DG |

Data control module |

Main control board, power supply AC220V, AC24V and DC12V board Data acquisition control module, supports remote power control and voltage and current data acquisition, voltage and current monitoring. |

|

7 |

IoT7000-UPS220-DG |

Delay UPS power supply |

Rated input AC100-240V, 50-60Hz, output DC12V/7.5A-80W power supply unit. UPS battery charge/discharge function connector, which can realize non-waiting power switching. The battery needs to be purchased separately. This power supply only provides DC12V battery charge and discharge connector. |

|

8 |

IoT90-LED |

LED lighting+Fan |

LED lighting automatically turns on when the box is opened and turns off when the box is closed. |

|

9 |

IoT90-ODF2 |

Fiber optical cable tray and adapter |

2 in and 2 out fiber optical cable tray 2*LC/LC or SC/SC fiber optical adapters |

|

10 |

IoT90-PWR100-AC24 |

AC24V power supply unit |

Rated input AC100-240V, 50-60Hz, Output AC24V/4.2A-100W power supply unit |

PACKING LIST

|

Packing List |

Content |

Qty |

Unit |

|

IoT intelligent power box |

1 |

Set |

|

|

User Guide |

1 |

PC |

|

|

Warranty Card and Certificate of Conformity |

1 |

PC |

TECHNICAL SPECIFICATION

|

Model |

ONV-IoT9000-CK-SI |

|

Power Configuration |

|

|

220V AC Power Air Circuit Breaker |

1*220V/16A |

|

220V AC Power SPD |

1*power SPD: 220V max: 40kA, Voltage protection Level ≤1.7kV Adding 1.2/50us (8-20us ) combined wave of L-N, 2KV does not cause to malfunction, 6KV is non-damaged, the upper limit is 10KV. |

|

Auto-reclosing |

Over-current protection/ action time: 16A/2-5S Over-voltage protection/ action time: AC275V/2-5S Electric leakage protection/ action time: 30mA/≤0.1S Under-voltage protection/ action time: AC145V/2-5S Detection function before closing, with remote control function Short circuit protection/ action time: 3 times input current/≤0.1S Working voltage: 175-275VAC 50-60Hz, Rated output current: 16A |

|

220V AC Power Output (Optional) |

4*AC220V/1A output, max load 220W, support voltage, and current detection, remote on/off control. 2P industrial terminal connection |

|

AC220V UPS Backup Power Output (Optional) |

1*Power-off alarm signal port. Rated input: AC100-240V, 50-60Hz, DC12V, AC220V two backup power output. Built-in balancing protection circuit, supports output overload, overvoltage, short circuit protection. |

|

AC24V Power Output (Optional) |

4*AC24V/2A output, max load 60W, support voltage, and current detection, remote on/off control. 2P industrial terminal connection. |

|

DC12V Power Output (Optional) |

4*DC12V/2A output, max load 24W, support voltage and current detection, remote on/off control. 2P industrial terminal connection. |

|

Power Consumption |

Standby<20W, Full Load<3500W |

|

Data Control Unit |

|

|

Main Control Chip |

CPU: ARM 108MHz, RAM: 1M Byte+64KByte, Flash: 512Byte |

|

Data Port |

1*RS485 data port, 1*RS232 data port |

|

Controlled I/O port |

1*Fan I/O control port, 1*Door status I/O detection port 1*Lighting I/O control port, 1*RS485 reclosing communication port 1*Power-off alarm I/O control port, 3*General DI interface for connecting peripheral |

|

Environmental Variable Monitoring |

Temperature/humidity monitoring, light intensity monitoring, OLED display screen status check |

|

Ethernet Port |

1*10/100Base-TX adaptive RJ45 port |

|

Ethernet Standard |

IEEE 802.3 10Base-T, IEEE 802.3u 100Base-TX |

|

LED Indicator |

Power (Green), Operation (Green), Fault (Red) |

|

Other |

|

|

Fan |

Built-in DC12V temperature control fan |

|

Box Door Lock |

Rust-proof mechanical door lock |

|

Disk Fiber Box |

1*2 in 2 out disk fiber box, 2*optical fiber connection adapters |

|

Storage Tray |

300*160*110mm |

|

Physical Parameter |

|

|

Operation Temp/ Humidity |

-20~+55°C, 5%~90% RH Non condensing |

|

Storage Temp/ Humidity |

-40~+85°C, 5%~95% RH Non condensing |

|

MTBF |

>100,000H |

|

Dimension |

600*440*300mm |

|

Net /Gross Weight |

<18kg/ <20kg |

|

Installation |

Pole hoop mount |

|

Certification& Warranty |

|

|

Lightning Protection |

Lightning protection: 6KV 8/20us, Protection level: IP55 |

|

Certification |

CE mark, commercial, CE/LVD EN62368-1, FCC Part 15 Class B, RoHS |

|

Warranty |

2 years, lifelong maintenance. |