OVERVIEW

The IoT7000-G2000-DG intelligent O&M module is a highly integrated, powerful, and easy-to-use and install data acquisition and control module. It uses a 1*main control unit and multiple controlled units (max 20 power output controls). Each unit board can be flexibly configured according to the application scenario. It is widely used in security monitoring boxes, power control boxes, traffic control boxes, and integrated control boxes. It has intelligent monitoring functions, which can realize mains electricity power failure detection, power consumption monitoring, temperature-controlled fans, remote power control, network transmission monitoring, box temperature monitoring, monitoring box anti-theft, and other functions. It interacts with the monitoring center operation and maintenance platform in real-time through the network to report the on-site situation. When there is a network interruption, equipment damage, mains electricity interruption, equipment power consumption status change, box temperature is too high, and the box door is forced to open, it will actively notify the monitoring center.

The IoT7000-G2000-DG has rich ports and powerful functions. It is used for the intelligent transformation and upgrading of old monitoring boxes and the establishment of IoT systems. It can effectively improve the reliability and stability of unattended systems at low cost, simplify maintenance methods, and improve operation and maintenance efficiency. It is suitable for the construction of smart security IoT projects including safe cities, smart transportation, smart cities, natural disaster monitoring, water conservancy facilities monitoring, and communication base station monitoring.

FEATURE

Power consumption monitoring

◇ Support 5 power supply unit combinations, each unit supports 4 power outputs, AC220V, AC24V, and DC12V three output voltages can be arbitrarily combined, and the max can be expanded to 20. Support output voltage and current monitoring, power failure alarm, and real-time upload of power consumption status and fault information to the management platform can distinguish the front-end reclosing (input) power failure and the back-end (output) power failure status.

◇ Support the backup power failure alarm function, and provide 1*AC220V backup power output, when the mains electricity is out of power, automatically switch to the built-in UPS power supply (delay 1 minute), to ensure that the equipment sends the power failure information back to the monitoring center in time.

Network communication monitoring

◇ 1*10/100M RJ45 port is connected to the switch or ONU, which can realize network status monitoring, upload network connectivity status and fault information to the management platform in real-time, support network watchdog function, can automatically analyze and judge the network status, when the network port communication is abnormal, can automatically restart the switch port power supply, and reset and repair the network status.

Remote control

◇ Support remote restart of camera/switch/PON device power supply to achieve remote fault repair. Support timing control, can run offline locally, does not rely on the monitoring center, and can still be executed as planned in the case of network interruption.

Fan control

◇ The temperature linkage value can be set remotely. When the temperature reaches the set value, the fan will automatically start working, and the working status of the fan will be monitored in real-time. A fault report will be issued when the fan works abnormally.

Lighting control

◇ The operation and maintenance controller has a built-in light sensing control circuit and provides a 1*DC12V LED light connection port to connect the LED light inside the box. When the door is opened or the external light intensity is low, the LED light inside the box automatically turns on, which is convenient for equipment inspection and maintenance. The platform can monitor the working status of the light in real-time, and the on/off status of the light is synchronously displayed on the platform.

Door tamper detection

◇ Provides 1 access control detection interface to connect to the box door detection switch to detect the box door status, prevent the equipment box from being opened abnormally, and prevent the equipment inside the box from being stolen. Supports arming, disarming, automatic disarming, and other mode settings.

Real-time status query

◇ The OLED display screen can directly query the status of cabinet variables (on/off, fan, temperature/humidity), the working status of each power supply, the network communication status, and other information to quickly detect the working condition of the cabinet.

Efficient operation and maintenance

◇ When the equipment is online, you only need to use the operation and maintenance APP mobile to scan the code to automatically enter the management platform system, no configuration, simple and convenient.

◇ After being connected to the Internet, it can remotely manage and view the operation of front-end equipment in real-time with the platform, monitor the power supply status of equipment, locate the installation location of equipment, realize fault alarm, fault location, remote control, automatic dispatch of work orders, etc., monitor the operation status of equipment boxes in real time, realize intelligence, and improve the reliability of unattended and automated system operation and maintenance.

◇ When an abnormality occurs in the front-end equipment, the alarm information will be reported to the platform or the management personnel will be notified. The platform will intelligently classify whether a maintenance work order is generated and form a QR code dispatch work order. The maintenance personnel can view the dispatched work order through the APP and troubleshoot the fault quickly. The centralized management cloud platform has alarm records, historical operation records, fault statistical analysis reports, and operation log records. All report records can be exported to provide data support for the improvement and optimization of the comprehensive operation and maintenance system.

PRODUCT PORT

|

Model |

IoT7000-G2000-DG |

|

Function & port |

|

|

AC220V input |

5 |

|

AC24V input |

5 |

|

DC12V input |

5+1 |

|

AC220V output |

4-20 |

|

AC24V output |

4-20 |

|

DC12V output |

4-20 |

|

AC220V UPS output |

1 |

|

RS485 port |

1 |

|

RS232 port |

1 |

|

DI/DO port |

3 |

|

10/100M RJ45 port |

1 |

|

Fan I/O port |

1 |

|

Lighting I/O port |

1 |

|

Box Door I/O port |

1 |

|

Water leakage detection I/O port |

1 |

|

Power-off alarm |

1 |

|

Reclosing RS485 port |

1 |

|

OLED display |

1 |

|

Power indicator (Green) |

1 |

|

System operation indicator (Green) |

1 |

|

Fault warning indicator (Red) |

1 |

|

Temperature/humidity monitoring |

Y |

|

Note: DC12V input, AC24V input, and AC220V input power need to be provided separately. The module must provide DC12V to work normally. The module has no power supply. |

|

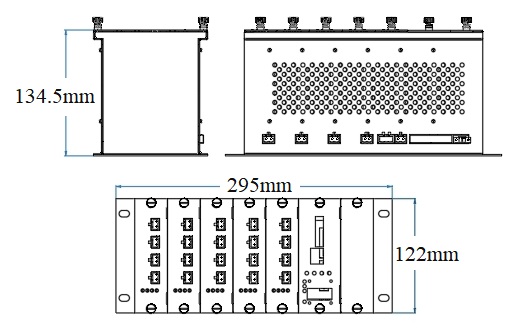

DIMENSION

OPTIONAL ACCESSORIES

|

Model |

Description |

|

IoT7000-UPS220-DG |

1*Power-off alarm signal port. Super capacitor design, no battery replacement. Aluminum alloy housing, super heat dissipation, and sturdy and durable. Rated input AC100-240V, 50-60Hz, two backup power outputs DC12V, AC220V. Built-in intelligent balancing protection circuit, supports output overload, overvoltage, and short circuit protection. |

PACKING LIST

|

Packing List |

Content |

Qty |

Unit |

|

IoT intelligent O&M module |

1 |

Set |

|

|

User Guide |

1 |

PC |

|

|

Warranty Card and Certificate of Conformity |

1 |

PC |

TECHNICAL SPECIFICATION

|

Model |

IoT7000-G2000-DG |

|

Power Input |

|

|

Input Working Voltage |

5*AC24V input, 2P industrial terminal connection 5*AC220V 50-60Hz input, 3P industrial terminal connection 6*DC12V input, 2P industrial terminal connection (1*DC12V input for main control board power supply) |

|

Power Output |

|

|

AC220V Power Output |

Each unit board supports 4*AC220V/1A output, max load 220W. support voltage and current detection, remote control on/off. 2P industrial terminal connection. Max expansion 20 outputs. |

|

AC220V UPS Backup Power Output |

1*AC220V UPS backup power output, support voltage current detection, remote on/off control, 2P industrial terminal connection |

|

AC24V Power Output |

Each unit board supports 4*AC24V/2.5A output, max load 60W. support voltage and current detection, remote control on/off. Max expansion 20 outputs. |

|

DC12V Power Output |

Each unit board supports 4*DC12V/2A output, max load 24W. support voltage and current detection, remote control on/off. 2P industrial terminal connection. Max expansion 20 outputs. |

|

Power Consumption |

Standby<20W, Full Load<2000W |

|

Data Control Unit |

|

|

Master Chip |

CPU: ARM 108MHz, RAM: 1M+64KByte, Flash: 512Byte |

|

Data Port |

1*RS485 data port, 1*RS232 data port (If ≥3 data ports are required, it can be realized through expansion board. |

|

Controlled I/O port |

1*Fan I/O control port, 1*Door status I/O detection port 1*Lighting I/O control port, 1*RS485 reclosing communication port 1*Power-off alarm I/O control port, 3*General DI port for connecting peripheral |

|

Environment Variable Monitoring |

Temperature/ humidity monitoring, light intensity monitoring, OLED display screen status check |

|

Ethernet Port |

1*10/100Base-TX adaptive RJ45 port |

|

Ethernet Standard |

IEEE 802.3 10Base-T, IEEE 802.3u 100Base-TX |

|

LED Indicator |

Power (Green), Operation(Green), Fault(Red) |

|

Physical Parameter |

|

|

Operation Temp/ Humidity |

-40~+70°C, 5%~90% RH Non condensing |

|

Storage Temp/ Humidity |

-40~+85°C, 5%~95% RH Non condensing |

|

MTBF |

>100,000H |

|

Dimension (L*W*H) |

295*134.5*122mm |

|

Net /Gross Weight |

<2.0kg/ <2.5kg |

|

Installation |

DIN Rail, wall mount (extendable to 19" rack) |

|

Certification & Warranty |

|

|

Lightning Protection |

Lightning protection: 6KV 8/20us, Protection level: IP30 |

|

Certification |

CCC, CE mark, commercial, CE/LVD EN62368-1, FCC Part 15 Class B, RoHS |

|

Warranty |

2 years, lifelong maintenance. |